In today’s busy world it is easy to forget to check and change the oil, clean or replace filters, blow out the dryers or coolers and all the other routine checks that keep medical air compressors, medical vacuum pumps and other source equipment running at its best.

Facilities personnel should consider that this vital life support equipment is just as valuable to your medical operations as electricity or water. If the medical air or vacuum acts up or quits, the disruption can mean expensive downtime, cause a major loss of revenue or even worse, a massive hit to your pocketbook in the case of a patient injury or death.

So, what are a few of the downsides to poor maintenance:

- Equipment will work harder

- Decreased overall efficiency

- Puts an increased load on pumps, motors and other moving parts

- Leads to higher than normal operating temperatures

- Causes parts and components to wear out faster

- Decreases the life span of the equipment

- Increases energy consumption and energy costs

- Overworked equipment may not be able to keep up with the demand

- In the case of a breakdown, expensive emergency service could be required

- Eventually the equipment will just quit from overuse and exhaustion

- Failure can put your system out of NFPA99 compliance

“Preventing” all of the above from happening is the job of a good preventative maintenance program. When your equipment is kept happy it pays back by performing better and lasting longer with little or no downtime.

In the case of source equipment, regular maintenance is mandated by NFPA99 codes (reference our blog post “Medical Gas Certifications and Qualifications . . .”). Those who are maintaining medical air and medical vacuum equipment must be ASSE 6040 certified and must have experience maintaining source equipment in order to be eligible to perform ANY service or repair on these systems.

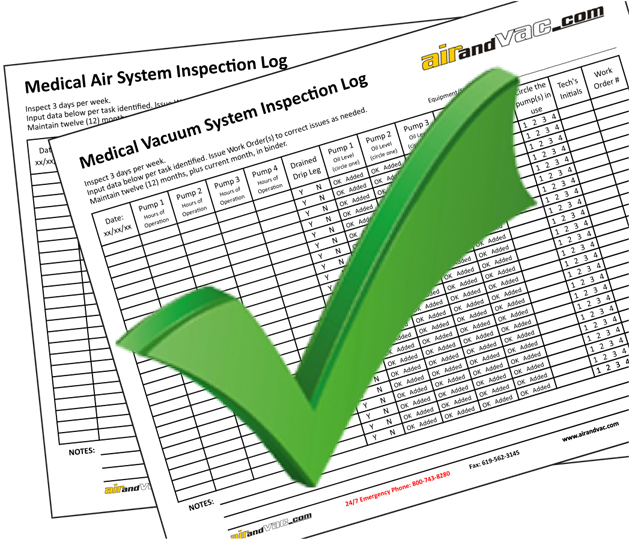

When it comes to medical air compressors and vacuum pumps, the word “inspection” is pretty heavy duty. Among other things, inspectors want to see your equipment maintenance paperwork. If you don’t have it the consequences can range from daunting to devastating.

airandvac.com can help you prevent trouble. Our service technicians are available to keep your equipment in tip-top shape and provide you with all of the paperwork necessary to keep the inspectors satisfied. Contact us for more information on Preventative Maintenance Programs.

And, by the way . . . our technicians are ASSE 6040, HIPAA and Bloodbourne Pathogens certified. We carry all the necessary insurances and liability coverage for taking care of your equipment. In the event of an emergency, we are available 24/7 to help get you out of any crisis situation.