Your hospital is growing like a weed. This is a GOOD thing!! To compensate for the growth, you may find that your existing medical air and medical vacuum systems are undersized for your new plan and require upsizing. This is also a good thing since you will be replacing old Nellie with up-to-code, state-of-the-art equipment.

When it comes time to do the major facility revamp, keep in mind that upsizing your equipment packages will most likely increase the overall footprint required for the machinery. Another important factor goes along with the upsizing equation. Take into account that your medical air or vacuum system also needs room to breathe.

When discussing architectural, engineering and construction designs with your team of professionals, make sure they understand that a certain amount of space is advised for helping to keep your source equipment maintained, cool and clean.

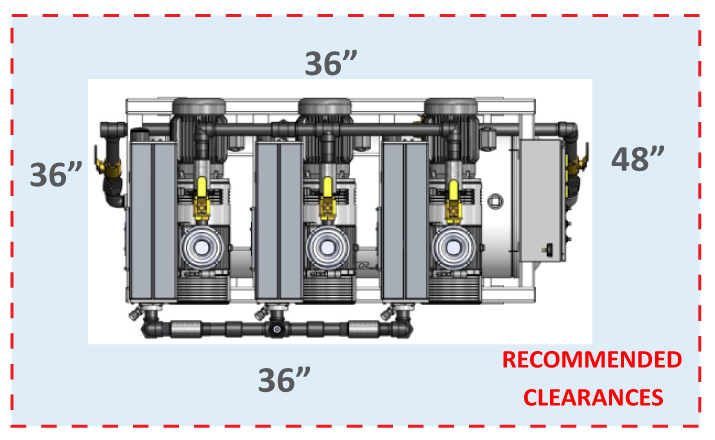

The general maintenance/ventilation recommendations for all four sides of your source equipment are:

- 36” on three sides

- 48” on the side of the equipment where the control panel will be located

- There are exceptions to this rule of thumb. Contact us and we can answer any questions you may have.

The space you allocate around your equipment directly effects the amount of time your maintenance crew or outside service company will need when servicing your medical air compressors and vacuum pumps.

The labor hours involved in servicing source equipment installed against walls or sandwiched in between other machinery, versus easy-access equipment, can add up quickly. Pay that extra amount each time you service your equipment in the future and watch the dollars pile up. Or get big kudos up front for a job well done by showing your design team the maintenance money saved in the long run.

Also consider that heat affects machinery in several detrimental ways. See our blog post “How Room Heat Affects Source Equipment”. Adequate ventilation and cooling are a must for your equipment to operate as efficiently as possible. You are investing a boatload of money in your new equipment. If you do not make adequate arrangements for service and heat removal it could have drastic effects on your factory warranty.

Easy-access, well ventilated equipment has lots of distinct advantages:

- The pumps and components will require less overall maintenance

- Pumps run cooler and more efficiently, minimizing power usage and energy costs

- Normal, stress-free operation increases the life span of the equipment

- Less downtime is required for unnecessary or emergency overheating repairs

- Less likelihood of a pump failing from heat exhaustion

- Appropriate accessibility and ventilation equate to lower maintenance fees

Thinking ahead during the planning stages can make your new equipment room work like a champ. We have lots of helpful ideas and suggestions. Contact us, we’d be happy to lend a hand.